Traction inverter for electric commercial vehicles (eCAVs)

Power up electric commercial & agricultural vehicles (eCAVs) with Infineon's system solutions for easy platform migration and fast time-to-market

Minimize switching losses, maximize thermal efficiency, and efficiently store regenerative braking energy with Infineon's traction inverter solutions for electric commercial vehicle drivetrains. Our comprehensive system solution offers the most scalable power portfolio, along with optimized gate-driver and MCU technology. Ensure ASIL-D functional safety through seamless component interoperability for sustained operational excellence.

Powerful and efficient traction inverters for eCAVs

The traction inverter in electric commercial vehicles plays an essential role in determining the vehicle's performance and efficiency. It regulates the motor's speed and torque, facilitates regenerative braking to recharge the battery, and ensures optimal power delivery. Advanced eCAV traction inverters prioritize high efficiency, low switching losses, and thermal management to enhance the overall system performance and extend the vehicle's driving range. Infineon offers a highly scalable system solution to meet the requirements of commercial vehicle traction inverters, allowing efficiency, fast time-to-market, and optimized performance.

Technology choice (Si and SiC) in traction inverter systems

SiC-based power electronics for traction inverters in electric commercial vehicles are accelerating rapidly. Given the WLTP mission profile, where partial load dominates, SiC demonstrates an efficiency gain of approximately 4% over its silicon counterpart. It is our belief that Si and SiC will coexist as both have their unique benefits. A Si/SiC combined solution is often considered for eCAV traction inverters and secondary inverters, i.e., SiC is applied for rear-wheel drive to extend the range, whereas Si IGBT is used in front-wheel drive to enable cost optimization.

Learn more about our products:

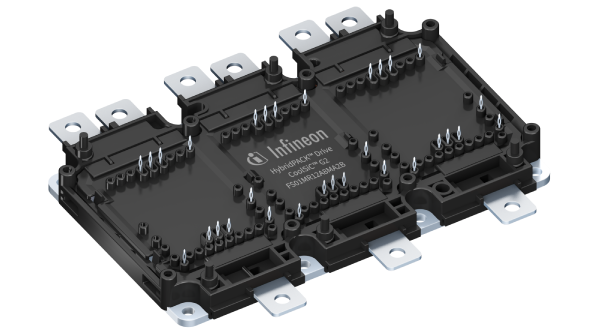

- Trench-based HybridPACK™ Drive CoolSiCTM G2 module FS0xMRxx

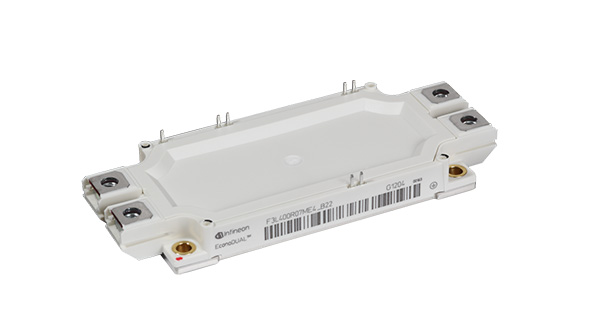

- IGBT7 based EconoDUAL half-bridge module FFx00R12ME7

- EDT2 based HybridPACK™ Drive G2 module FSxxxRxx

- EiceDRIVER™ 1EDI303xAS optimized for CoolSiC™

- Coreless current sensor: Swoboda CSM510HP2x with Infineon TLE4973

- 32-bit AURIX™ microcontrollers TC3xx

- OPTIREG™ PMICs (Automotive) - integrated, multi-rail power supply solutions

Build dependable solutions based on ISO 26262

Highly integrated systems equipped with safe electronic semiconductors are essential for key applications like eCAV inverter. The ISO 26262 standard sets out requirements and guidance for products to integrated in automotive safety applications. With our holistic approach towards functional safety, Infineon is fast responding to the increased complexity and strict requirements of functional safety. Infineon provides complete inverter system products, including documentation and supporting information, for easing the design-in and reduce the effort at system integration level.

Evaluation kit based on HybridPACK™ Drive CoolSiC™ G2

Evaluation kit for fast design-in, including:

- HybridPACK™ Drive CoolSiC™ G2, sintered, ceramic, direct cooling and on-chip temperature sensing

- Gate driver board with EiceDRIVER™ G3

- Logic board with AURIX™ MCU

- Communication and development interface: CAN, USB, DAP

- Software supports flexible operational modes

- One-eye GUI interface enabling full customization

- Current sensor vertically integrated into the busbar for optimized space and cost

- Aluminum cooler in reference design, plastic cooler as optional

- DC link capacitor

New white paper about electrified heavy-duty vehicles

Electrification as a key to reducing emissions and improvements in energy storage technology and developments in supplemental infrastructure enables the fully autonomous long-haul operation. Standardization for autonomous trucks, busses, and in-city delivery vehicles needs to improve to support cross-border or even cross-continental interoperability.

This whitepaper covers the electrification of heavy-duty vehicles focusing on battery, charging, drive train, and power semiconductor aspects. Learn more about the technical bits and pieces to solve this global puzzle in this white paper.

Podcast4Engineers: Electric commercial, construction and agricultural vehicles (eCAV)

E-mobility is not only a hot topic but also a broad one. Our experts paint the picture of electromobility in our podcast series, ranging from toy-sized hoverboards to oversized mining trucks and many vehicle applications in between. Learn how Infineon is helping to make the world of transportation easier, safer and greener.

In this training, you will:

- to know about the market trend “Electrification” in commercial, construction, and agricultural vehicles (CAV)

- Understand the importance of customer enablement and how Infineon serves eCAV

Webinars

With proven expertise and a comprehensive portfolio of robust, high-quality control and power semiconductor solutions, Infineon helps you engineer successful and reliable designs for commercial, construction and agricultural vehicles.

Key Takeaways:

1.Understand how Infineon responds to the trends in the CAV market

2.Get an overview of different applications: Main drive, auxiliaries

3.Learn about the system solutions with power modules, gate drivers, microcontrollers AURIX™, sensors, and more