Tough times!

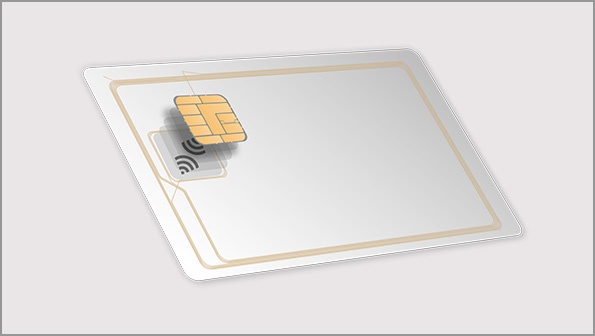

Today’s contactless and DIF cards don’t have it easy. Stuffed into a wallet, they get sat on, bent, twisted, squashed and thrown about all day long. What’s more, they get pulled out and shoved back in to the wallet every time the user wants to buy a coffee, ride the subway, enter a building, pay for shopping or collect a prescription from the drugstore. The constant mechanical strain through rough daily handling means that the conventional physical connection between the radio frequency (RF) antenna and the card module can easily snap. And it frequently does.

Why Infineon

With our field-proven, plug & play packaging technology based on inductive coupling, we offer our customers a smart solution for the transition from contact-based to contactless using CoM DIF cards. Our CoM packages featuring polycarbonate monoblocks meet all security and robustness requirements for government identification or payment cards in particular, effortlessly overcoming the weak spot in today’s dual-interface card designs.

Maintaining lean production processes identical to those deployed in contact-based environments, our customers can look forward to immediate, high-speed volume production without having to invest in any new or special machinery. In addition, they benefit from a simplified, secure supply chain with reduced stock levels as one antenna supports all chip/module combinations.

As the leading provider of security solutions with a track record stretching back more than 30 years, we have developed an excellent worldwide sales and customer support structure over time. Presenting a single point of accountability, our one-stop, global offering extends beyond chips to include the operating system, module and antenna for reduced production complexity.